-

Desk of Contents

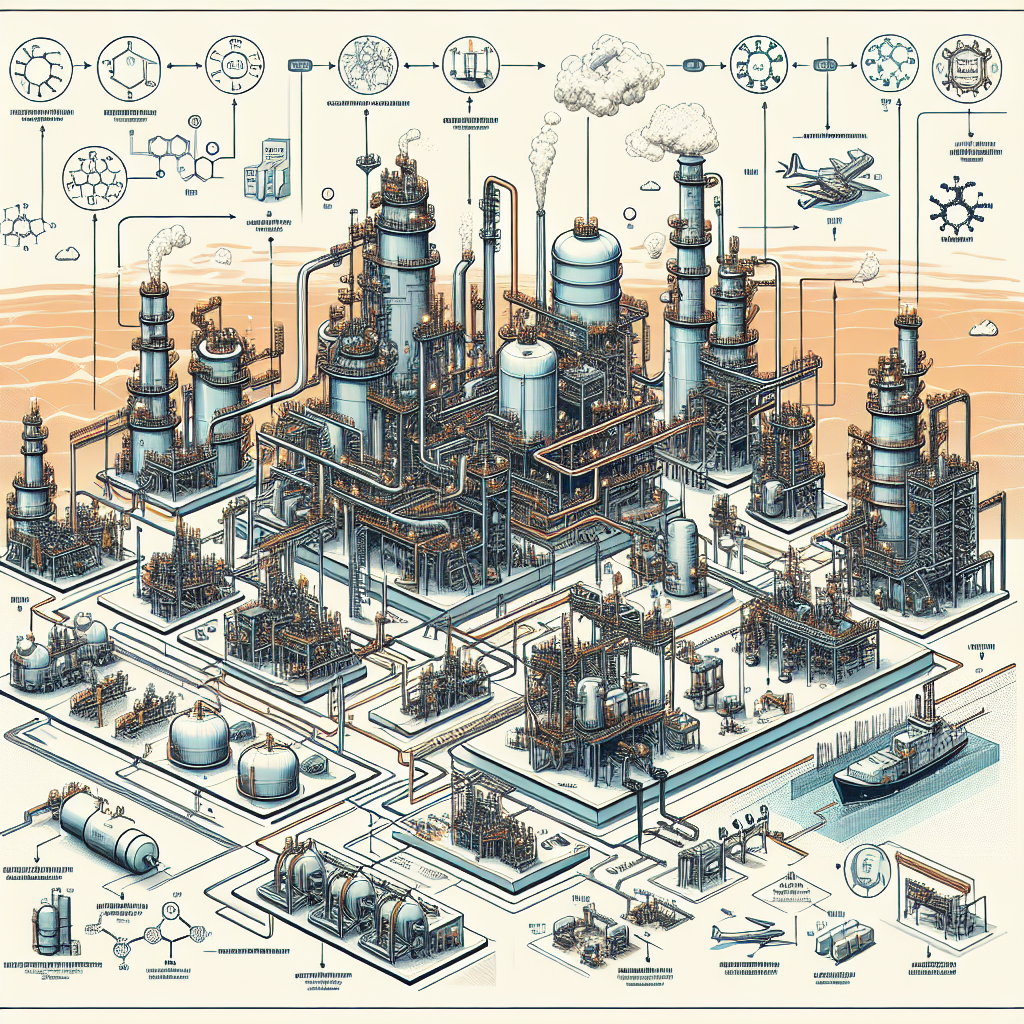

“Revolutionizing Tomorrow: Slicing-Edge Applied sciences for Environment friendly Petrochemical Refinement.”

The petrochemical business is present process a major transformation pushed by the most recent applied sciences in refinement processes. Improvements equivalent to superior catalytic processes, digitalization, and automation are enhancing effectivity, lowering environmental influence, and optimizing useful resource utilization. Strategies like hydrocracking, fluid catalytic cracking, and the mixing of synthetic intelligence for predictive upkeep are revolutionizing conventional strategies. Moreover, the adoption of sustainable practices, together with carbon seize and utilization, is turning into more and more essential because the business seeks to align with world environmental targets. These developments not solely enhance manufacturing yields but additionally pave the way in which for the event of greener and extra sustainable petrochemical merchandise.

Advances in Catalytic Cracking Applied sciences

The petrochemical business has witnessed important developments in catalytic cracking applied sciences, which play a vital function within the conversion of crude oil into priceless merchandise equivalent to gasoline, diesel, and varied petrochemicals. Catalytic cracking, a course of that breaks down massive hydrocarbon molecules into smaller, extra helpful ones, has developed significantly through the years, pushed by the necessity for elevated effectivity, lowered environmental influence, and the flexibility to course of a wider vary of feedstocks. Because the demand for cleaner fuels and extra sustainable practices grows, the most recent improvements on this discipline are reshaping the panorama of petrochemical refinement.

One of the notable developments in catalytic cracking is the event of latest catalyst formulations. Conventional zeolite catalysts have been enhanced with superior supplies that enhance their exercise and selectivity. As an example, researchers have been exploring the usage of hierarchical zeolites, which possess a novel pore construction that enables for higher diffusion of reactants and merchandise. This innovation not solely will increase the yield of fascinating merchandise but additionally minimizes the formation of undesirable byproducts, thereby optimizing the general effectivity of the cracking course of. Moreover, the incorporation of metallic nanoparticles into zeolite frameworks has proven promise in enhancing catalytic efficiency, permitting for more practical cracking of heavier feedstocks.

Along with catalyst enhancements, the mixing of superior course of applied sciences has additionally contributed to the evolution of catalytic cracking. The implementation of steady catalytic cracking (CCC) methods represents a major shift from conventional batch processes. CCC methods allow a extra steady and environment friendly operation by permitting for the continual feeding of feedstock and removing of merchandise. This not solely enhances throughput but additionally reduces downtime related to catalyst regeneration and upkeep. Furthermore, the usage of real-time monitoring and management methods in CCC setups permits for exact changes to working situations, guaranteeing optimum efficiency and product high quality.

One other space of innovation is the event of hybrid catalytic cracking processes that mix conventional catalytic strategies with various applied sciences equivalent to microwave-assisted cracking. This method leverages the distinctive heating capabilities of microwaves to reinforce the cracking response, leading to improved product yields and lowered power consumption. By integrating these applied sciences, refiners can obtain a extra versatile and environment friendly operation, able to adapting to various feedstock qualities and market calls for.

As environmental laws develop into more and more stringent, the petrochemical business can also be specializing in lowering emissions related to catalytic cracking. The newest applied sciences purpose to reduce the discharge of greenhouse gases and different pollution by means of the implementation of carbon seize and storage (CCS) methods. By capturing CO2 emissions generated through the cracking course of, refiners can considerably decrease their carbon footprint, aligning with world sustainability targets. Moreover, developments in course of design, equivalent to the usage of warmth integration methods, assist to get better and reuse power inside the system, additional enhancing general power effectivity.

In conclusion, the most recent developments in catalytic cracking applied sciences are remodeling the petrochemical refinement panorama. By way of the event of revolutionary catalysts, the adoption of steady processing methods, and the mixing of other applied sciences, the business is shifting in direction of extra environment friendly and sustainable practices. As these applied sciences proceed to evolve, they won’t solely meet the rising demand for cleaner fuels but additionally contribute to a extra environmentally accountable petrochemical sector. The continuing analysis and growth on this discipline promise to unlock new potentialities, guaranteeing that catalytic cracking stays a cornerstone of recent petrochemical refinement.

Improvements in Course of Optimization Software program

Within the quickly evolving panorama of petrochemical refinement, improvements in course of optimization software program have emerged as a pivotal pressure driving effectivity and sustainability. Because the business grapples with growing regulatory pressures and the necessity for cost-effective operations, superior software program options are being developed to reinforce the efficiency of refining processes. These improvements leverage subtle algorithms and information analytics to optimize varied phases of manufacturing, from feedstock choice to product distribution.

One of the important developments in course of optimization software program is the mixing of synthetic intelligence (AI) and machine studying (ML) applied sciences. These instruments allow refineries to investigate huge quantities of operational information in real-time, figuring out patterns and anomalies that human operators would possibly overlook. By using predictive analytics, refineries can anticipate gear failures, optimize upkeep schedules, and scale back downtime, finally resulting in elevated throughput and decrease operational prices. Moreover, AI-driven fashions can simulate completely different refining eventualities, permitting operators to make knowledgeable choices that improve yield and decrease waste.

Along with AI and ML, the adoption of cloud computing has remodeled the way in which course of optimization software program is deployed and utilized. Cloud-based platforms facilitate seamless information sharing and collaboration amongst varied stakeholders, together with engineers, operators, and administration groups. This connectivity not solely enhances communication but additionally permits for the mixing of disparate information sources, equivalent to sensor information, historic efficiency metrics, and market traits. Because of this, refineries can obtain a holistic view of their operations, enabling extra knowledgeable decision-making and strategic planning.

Furthermore, the event of superior course of management (APC) methods has considerably improved the precision and reliability of refining operations. These methods make the most of real-time information to regulate course of parameters dynamically, guaranteeing that operations stay inside optimum ranges. By minimizing variability in manufacturing, APC methods contribute to increased product high quality and consistency, that are essential in assembly stringent business requirements. Moreover, these methods will be built-in with current management architectures, permitting for a smoother transition and minimizing disruption throughout implementation.

One other noteworthy innovation is the usage of digital twins within the petrochemical business. A digital twin is a digital illustration of a bodily asset or course of, created utilizing real-time information and superior modeling methods. By simulating the conduct of refining processes, digital twins allow operators to check varied eventualities and assess the influence of potential modifications with out risking precise manufacturing. This functionality not solely enhances course of understanding but additionally helps steady enchancment initiatives by offering insights into efficiency bottlenecks and optimization alternatives.

Moreover, the emphasis on sustainability has led to the event of software program options that concentrate on power effectivity and emissions discount. These instruments analyze power consumption patterns and determine alternatives for optimization, equivalent to warmth integration and waste warmth restoration. By minimizing power utilization and emissions, refineries cannot solely adjust to environmental laws but additionally enhance their general profitability.

In conclusion, the most recent improvements in course of optimization software program are reshaping the petrochemical refinement panorama. By harnessing the facility of AI, cloud computing, superior course of management, digital twins, and sustainability-focused options, refineries are higher outfitted to navigate the complexities of recent manufacturing. As these applied sciences proceed to evolve, they promise to reinforce operational effectivity, scale back prices, and assist the business’s transition in direction of a extra sustainable future. The continuing integration of those superior instruments will undoubtedly play a vital function in defining the following technology of petrochemical refinement.

Affect of Synthetic Intelligence on Refinery Operations

The mixing of synthetic intelligence (AI) into petrochemical refinement processes is revolutionizing the business, enhancing operational effectivity, and driving important price reductions. As refineries face growing strain to optimize manufacturing whereas minimizing environmental influence, AI applied sciences are rising as essential instruments for attaining these aims. By leveraging huge quantities of knowledge generated throughout refining operations, AI methods can analyze patterns, predict outcomes, and facilitate decision-making processes that have been beforehand reliant on human instinct and expertise.

One of the important impacts of AI in refinery operations is its means to optimize course of management. Conventional refining processes usually contain advanced variables that may be tough to handle successfully. Nonetheless, AI algorithms can analyze real-time information from varied sensors and management methods, permitting for dynamic changes to be made in response to altering situations. This functionality not solely enhances the effectivity of the refining course of but additionally improves product high quality by guaranteeing that the specified specs are persistently met. As an example, machine studying fashions can predict the optimum working situations for various feedstocks, enabling refineries to maximise yield and decrease waste.

Furthermore, AI-driven predictive upkeep is remodeling how refineries handle their gear. By using machine studying methods, refineries can analyze historic information to determine patterns that precede gear failures. This proactive method permits for well timed upkeep interventions, lowering unplanned downtime and lengthening the lifespan of essential property. Because of this, refineries can function extra reliably and effectively, finally resulting in elevated profitability. The shift from reactive to predictive upkeep not solely enhances operational efficiency but additionally contributes to a safer working surroundings by minimizing the dangers related to gear failures.

Along with optimizing operations and upkeep, AI can also be enjoying a pivotal function in provide chain administration inside the petrochemical sector. The complexity of worldwide provide chains necessitates subtle forecasting and planning capabilities. AI algorithms can analyze market traits, demand fluctuations, and logistical constraints to offer extra correct predictions of provide and demand dynamics. This enhanced visibility permits refineries to make knowledgeable choices relating to manufacturing schedules, stock administration, and distribution methods. Consequently, refineries can reply extra agilely to market modifications, lowering extra stock and related carrying prices.

Moreover, AI applied sciences are facilitating developments in environmental compliance and sustainability efforts inside the petrochemical business. By monitoring emissions and different environmental parameters in real-time, AI methods can assist refineries guarantee compliance with regulatory requirements whereas figuring out alternatives for lowering their carbon footprint. For instance, AI can optimize power consumption throughout varied processes, resulting in decrease greenhouse gasoline emissions and improved general sustainability. This alignment with environmental targets is more and more essential as stakeholders demand higher accountability and transparency from the petrochemical sector.

Because the business continues to evolve, the adoption of AI applied sciences in refinery operations is predicted to speed up. The continuing growth of extra subtle algorithms and information analytics instruments will additional improve the capabilities of AI methods, enabling refineries to attain unprecedented ranges of effectivity and productiveness. In conclusion, the influence of synthetic intelligence on refinery operations is profound, driving enhancements in course of optimization, predictive upkeep, provide chain administration, and environmental compliance. As these applied sciences mature, they are going to undoubtedly play a vital function in shaping the way forward for petrochemical refinement, guaranteeing that the business stays aggressive and sustainable in an more and more advanced world panorama.

Sustainable Practices in Petrochemical Refinement Applied sciences

The petrochemical business has lengthy been a cornerstone of recent economies, offering important supplies for numerous merchandise. Nonetheless, as environmental considerations intensify, the sector is more and more adopting sustainable practices in petrochemical refinement applied sciences. These developments not solely purpose to scale back the ecological footprint of refining processes but additionally improve effectivity and profitability. One of the important traits on this space is the mixing of superior catalytic processes. Catalysts play a vital function in refining by facilitating chemical reactions at decrease temperatures and pressures, thereby minimizing power consumption. Current improvements in catalyst design, equivalent to the event of biocatalysts and nanocatalysts, have proven promise in bettering selectivity and yield whereas lowering dangerous byproducts.

Furthermore, the implementation of course of intensification methods is gaining traction. This method entails optimizing current processes to attain increased effectivity and decrease useful resource consumption. As an example, applied sciences equivalent to microreactors and membrane separation methods permit for extra exact management over response situations, resulting in enhanced product high quality and lowered waste technology. By streamlining operations, refiners cannot solely minimize prices but additionally align with sustainability targets, making course of intensification an important part of recent petrochemical refinement.

Along with these technological developments, the adoption of round economic system ideas is reshaping the panorama of petrochemical refinement. This paradigm shift emphasizes the significance of reusing and recycling supplies to reduce waste. For instance, the mixing of waste-to-energy applied sciences permits refiners to transform byproducts and waste supplies into priceless power sources, thereby lowering reliance on fossil fuels. Moreover, the event of chemical recycling strategies permits the transformation of plastic waste again into feedstock for brand new petrochemical merchandise, successfully closing the loop within the manufacturing cycle.

Transitioning to renewable feedstocks is one other essential side of sustainable practices in petrochemical refinement. The business is more and more exploring bio-based options to conventional fossil fuel-derived feedstocks. Improvements in biomass conversion applied sciences, equivalent to pyrolysis and gasification, are enabling the manufacturing of biofuels and biochemicals that may seamlessly combine into current refining processes. This shift not solely reduces greenhouse gasoline emissions but additionally enhances power safety by diversifying the feedstock provide.

Moreover, digital applied sciences are enjoying a transformative function in enhancing sustainability inside the petrochemical sector. The implementation of superior information analytics, synthetic intelligence, and machine studying permits for real-time monitoring and optimization of refining processes. By leveraging these applied sciences, refiners can determine inefficiencies, predict gear failures, and optimize useful resource allocation, finally resulting in lowered power consumption and decrease emissions. The digitalization of operations additionally facilitates higher decision-making, enabling corporations to reply swiftly to altering market calls for whereas adhering to sustainability commitments.

Because the petrochemical business continues to evolve, collaboration amongst stakeholders is crucial for driving sustainable practices ahead. Partnerships between refiners, know-how suppliers, and analysis establishments can speed up the event and deployment of revolutionary options. By sharing information and sources, the business can collectively deal with the challenges posed by local weather change and useful resource shortage.

In conclusion, the most recent applied sciences in petrochemical refinement are more and more targeted on sustainability, pushed by the necessity to decrease environmental influence whereas sustaining financial viability. By way of developments in catalytic processes, course of intensification, round economic system ideas, renewable feedstocks, and digital applied sciences, the business is poised to remodel its operations. As these sustainable practices acquire momentum, they not solely promise to reinforce the effectivity and profitability of petrochemical refinement but additionally contribute to a extra sustainable future for the planet.

Q&A

1. **Query:** What’s the function of digital twins in petrochemical refinement?

**Reply:** Digital twins are used to create digital fashions of bodily processes, permitting for real-time monitoring, predictive upkeep, and optimization of refinery operations.

2. **Query:** How is synthetic intelligence (AI) being utilized in petrochemical refinement?

**Reply:** AI is utilized for course of optimization, predictive analytics, and bettering decision-making by analyzing massive datasets to reinforce effectivity and scale back downtime.

3. **Query:** What developments have been made in catalyst know-how for petrochemical processes?

**Reply:** Current developments embody the event of extra environment friendly and selective catalysts that improve response charges and scale back power consumption, resulting in decrease operational prices.

4. **Query:** How is carbon seize and storage (CCS) know-how impacting petrochemical refinement?

**Reply:** CCS know-how is being built-in into petrochemical processes to scale back greenhouse gasoline emissions by capturing CO2 produced throughout refining and storing it underground or repurposing it.

Conclusion

The newest applied sciences in petrochemical refinement, together with superior catalytic processes, digitalization, and sustainable practices, are considerably enhancing effectivity, lowering environmental influence, and optimizing useful resource utilization. Improvements equivalent to machine studying for predictive upkeep, carbon seize and storage (CCS), and the mixing of renewable power sources are remodeling conventional refining operations. Because the business continues to evolve, these applied sciences are essential for assembly regulatory calls for and addressing the worldwide shift in direction of sustainability, finally resulting in a extra resilient and environmentally accountable petrochemical sector.